MW-960M

Batch Type MW Plasma Cleaning

Introduction

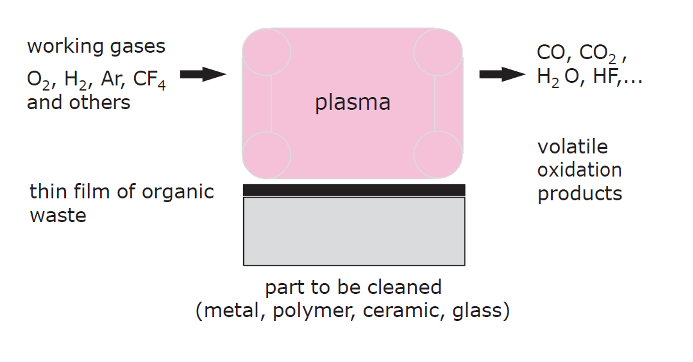

• Microwave

- High density of neutral atomic oxygen relative to ions.

-

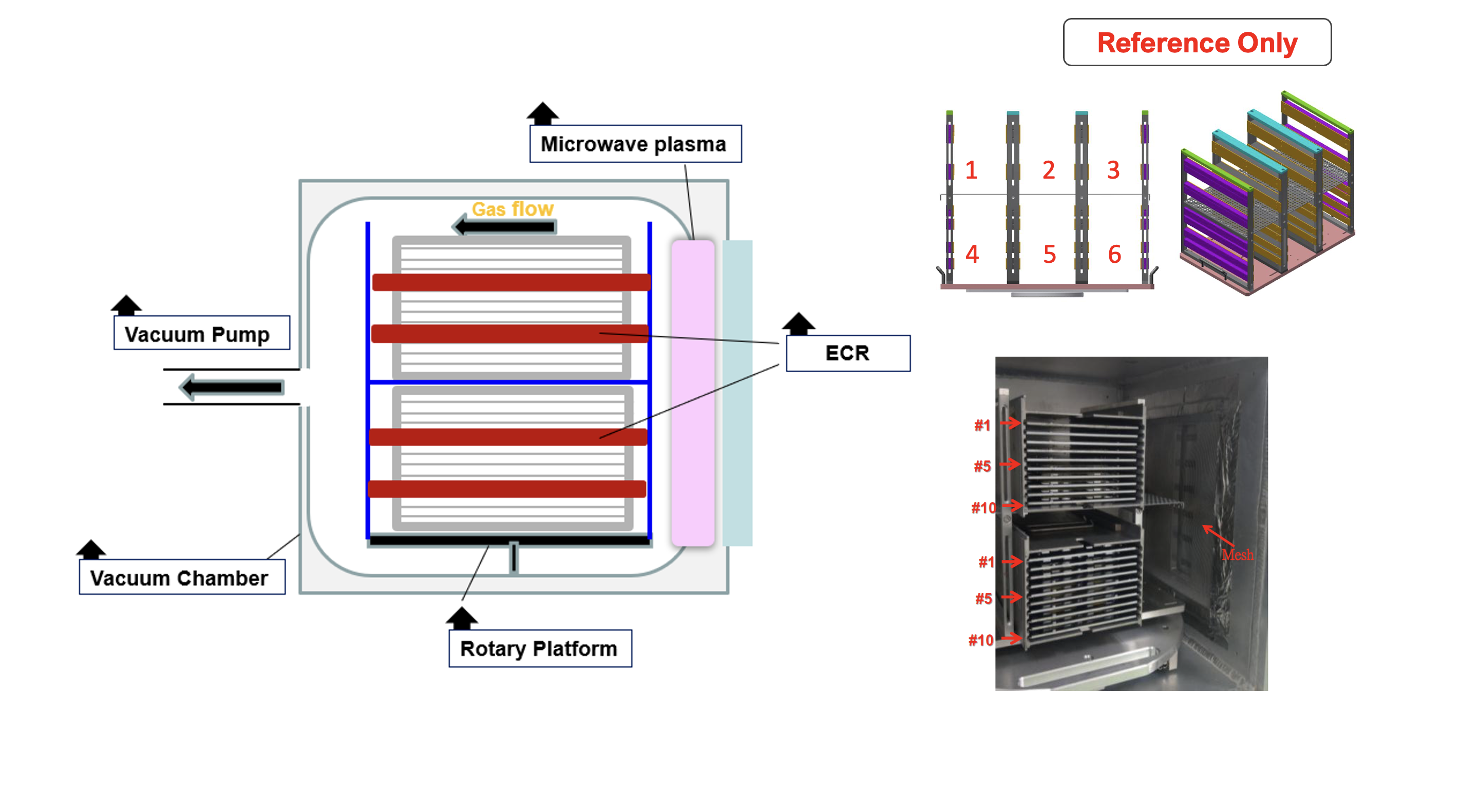

Rack for magnetic field designed.

High efficiency, uniformity microwave power delivery.

High ash rate (4~7 um/min).

• Microwave Plasma

-

No UV exposure

- ECR Plasma produce around magazines to increase clean ability

- Cool plasma before reaching the product

• Application

- Wire bond

- Mold

- Flip Chip Underfill

MW-960 Microwave Plasma Clean (Batch)

MW-960 is a versatile plasma processing system for IC assembly applications. Either slotted or slot-less magazines can be performed for various processes

• Applications

- Surface cleaning and activation prior to epoxy molding

- Surface cleaning and activation prior to wire bonding

- Surface cleaning and activation prior to underfill dispensing

- Surface cleaning and activation prior to solder ball attach

- Anti-tackiness treatment

• Features

- Microwave power supply generates high density plasma species to enhance the processing speed

- Electrode-free plasma source to eliminate the risk of electrostatic damage(ESD)

- Pulse mode operation can reduce the processing temperature

- Rotating rack enhance the process uniformity

- Plasma species trapped at both sides of slotted magazines enhanced the high yield of underfill dispensing

Chamber Mechanism

Lead Frame 水滴角均勻性測試

- Experimental lead frame 144 mm(L) by 60 mm(W)

- Water drop angle values are less than 40 degree with magazine type.