TGV workshop

TGV workshop

E&R has been dedicated to develop glass micro-machining techniques employed in the MEMS, display and WLO(Wafer Level Optics) devices. This patented technology is applicable to fabricate various geometric shapes.

-

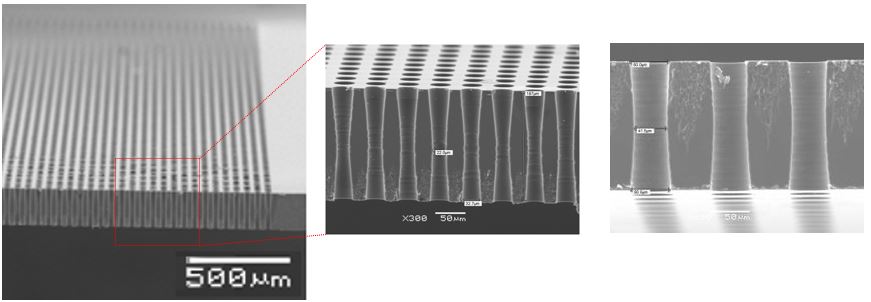

Through Glass Via, TGV, is usually employed as the glass interposer, 3D sensing or WLO devices

-

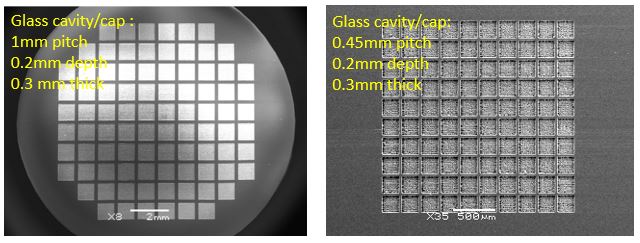

Glass cavity, cap or spacer, to form the hermetic seal, is usually employed for MEMS or WLO packaging

-

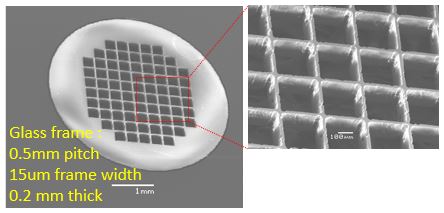

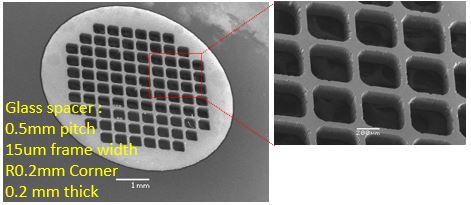

Glass frame/mesh

-

Free-form, according to customer’s requirement

-

Free from machining defects, e.g. crack and chipping

-

Feature scale as small as 15um

-

Wafer process, compatible with existed facilities

-

Fast throughput

-

Cost effective solution, in terms of material cost and initial investment

E&R is happy to provide process development and small-scale production services.

-

Our processes can be easily customized for a variety of glasses and extended to the other materials, e.g. quartz and sapphire.

TGV |

Material |

Borosilicate/Quartz |

Wafer size |

Φ8” |

Thickness |

50 - 400μm |

Via diameter |

Φ15 μm, minimum |

Diameter variation |

±5% |

Aspect ratio |

10 : 1, maximum |

Glass cavity / cap

Material |

Borosilicate |

Wafer size |

Φ8” |

Thickness |

50 - 400μm |

Cavity dimension |

φ0.2mm/□0.2mm, minimum |

Cavity shape |

customization |

Chipping |

≦10um |

Glass frame / spacer |

Material |

Borosilicate |

Wafer size |

Φ8” |

Thickness |

100 - 400μm |

Dimension |

Φ0.3mm/□0.3mm, minimum |

Shape |

customization |

Chipping |

≦30um |

Corner radius |

≧30um |