Hybrid laser & plasma drilling

WLCSP offers the most simplistic process flow while providing the IC with the smallest form factor and possible 6-face protection. Hence WLCSP is getting more and more popular.

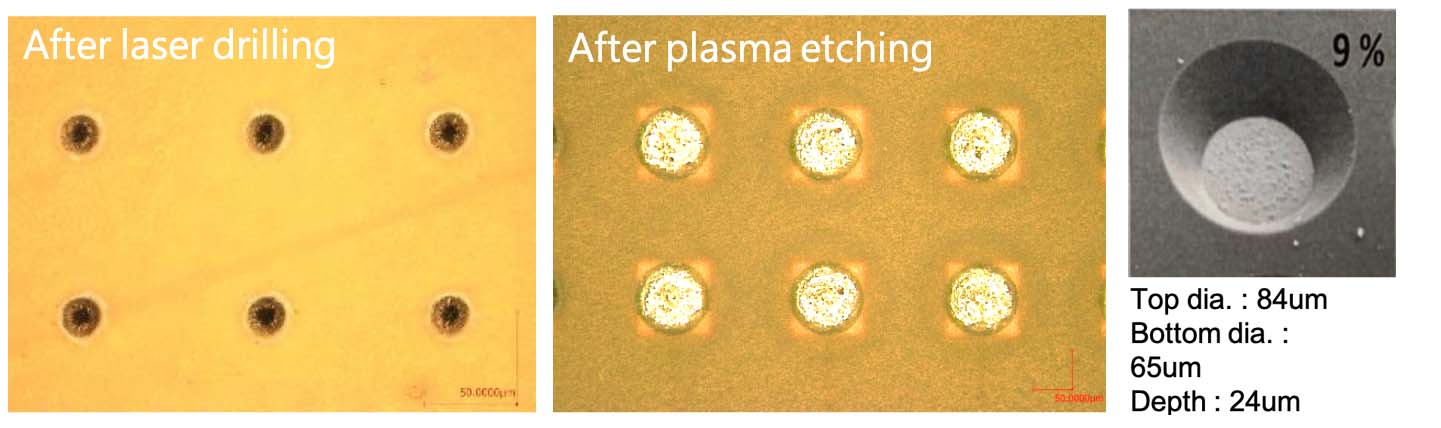

E&R provides an cost effective solution of hybrid laser & plasma drilling to form vias on the top passivation layer prepared for post bumping process.

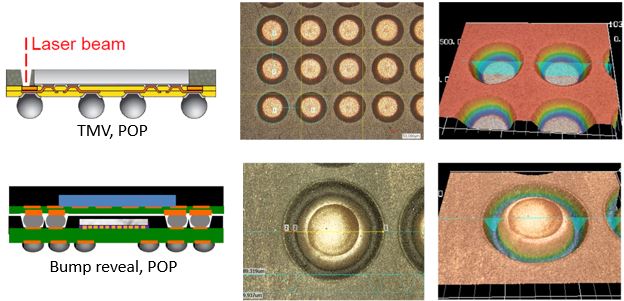

For fan-out process, stacked molded IC, Package-On-Package(POP) assembly, can increase the functionalities and reduce the form factor. Laser machining is an effective way either to drill the Through Mold Via(TMV) or reveal the buried bumps from the bulk EMC substrate.

E&R’s laser system can fulfill both fabrications precisely, thanks to its precise alignment algorithm.

Laser drilling removes most material firstly and then plasma etching removes less material to reach the final via dimension. The advantages compared with the traditional lithographic process, including :

- Simple and flexible process

- Cost effective

- High aspect ratio reachable

-

Protrusion of sidewall fillers can be eliminate