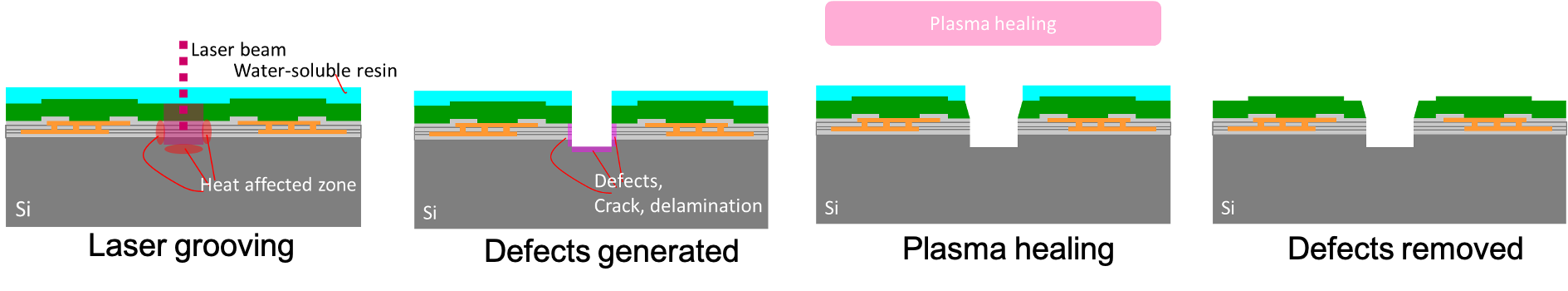

Plasma healing

Grinding marks on the wafer backside propagating into the buck silicon material will weaken the chip strength.

Micro-crack generated by the laser grooving along the edges of the chip propagating into the active area will induce the early failure of this chip.

So-called, plasma healing can remove both defects effectively and the bending strength of the chip can be increased.

E&R’s plasma system can remove the grinding marks and micro-cracks to increase the high production yield. Thanks to dry etching at the low temperature, either back-grinding tape or dicing tape can be kept intact during processing. In case the wafer is mounted on the tape with backside upward, both grinding and grooving defects can be removed simultaneously.

Grinding mark left on the wafer backside, before plasma healing

Grinding mark removed from the wafer backside, after plasma healing

Heat Affected Zone(HAZ) left on the sidewalls and bottom of the groove after laser grooving , before plasma healing

Heat Affected Zone(HAZ) removed, after plasma healing