EMC residue removal

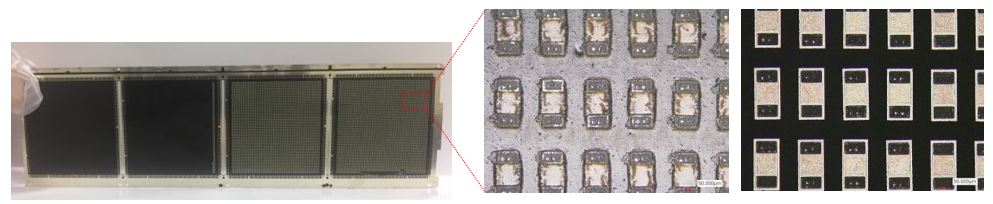

Epoxy Molding Compound(EMC) is widely employed in the advanced IC assembly processes, e.g. Molded Wafer-Level CSP(Fan-in process), Fan-out process. Either wafer-form or panel-form, compound bleeding, so-called flash, left on the chip surface during the molding process will reduce the production yield.

Plasma treatment, so-called plasma deflash, is an effective way which can completely remove the EMC residue and is harmless to the beneath materials, e.g. copper, nickel, gold, solder, silicon oxide and silicon.

EMC residue left on the top of solder bumps, Molded WLCSP, before plasma treatment.

EMC residue removed from the top of solder bumps, Molded WLCSP, after plasma treatment.

|

||

|

|

EMC residue left on the top of metal pads,before plasma treatment. |

EMC residue removed from the top of metal pads,after plasma treatment. |

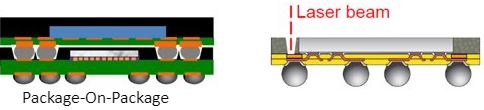

For fan-out process, stacked molded IC, Package-On-Package(POP) assembly, can increase the functionalities and reduce the form factor. Laser drilling is an effective way to form the Through Mold Via(TMV), especially in a large area. But usually EMC residue, so-called smear left at the via bottom will degrade the solderability in the subsequent reflow process and induce the early failure of this IC.

Plasma treatment, so-called plasma desmear, is an effective way which can completely remove the EMC residue and is harmless to the beneath metal layer, e.g. copper, nickel, gold and solder. Plasma desmear is also helpful to widen the process window of laser drilling, to prevent the damage of bottom metals and raise the drilling throughput.

EMC residue left, Before plasma treatment

EMC residue removed, After plasma treatment