Plasma dicing

Once chips on the wafer become smaller & thinner, traditional dicing technique, e.g. blade saw, faces many challenges, including high-percentage material loss resulted from the width of the dicing street, mechanical damage such as chipping, and unacceptable processing time.

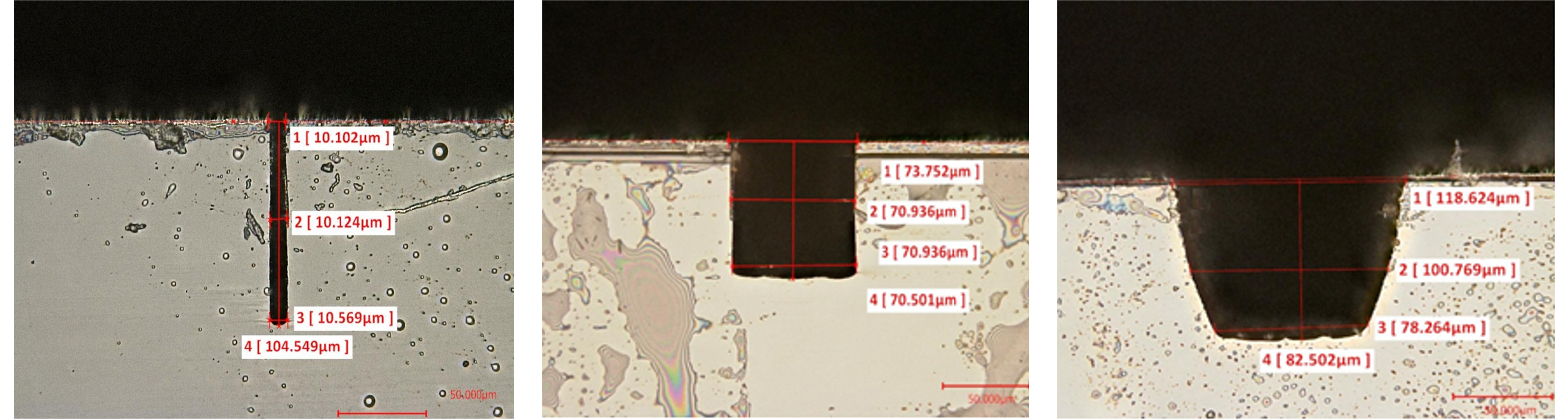

Plasma dicing is a process which uses a dry etching, where all the dicing lanes on the same wafer are cut simultaneously, without die stressing, no contamination, and several-folds in wafer dicing throughput. Also, more chips can be designed onto the wafer as narrower dicing lanes can be employed.

E&R’s plasma dicing system apply unique Microwave etching technology to generate following advantages.

● Low temperature process, no risk to damage the dicing tape.

● No ESD damage in light of downstream plasma

● Non-scallop process, without stress concentration

● Applicable for non-rectangular dicing

● Multiple smaller wafers in-parallel processing

● Low Cost-of-Ownership